Choosing the Right EOT Crane: A Complete Guide for Industrial Buyers

Selecting the appropriate Electric Overhead Traveling (EOT) crane is pivotal for optimizing operational efficiency and ensuring workplace safety in industrial settings. With various types and specifications available, making an informed decision can be challenging. This guide provides insights into key considerations to help you choose the ideal EOT crane for your industrial needs.

1.Assess Your Load Requirements

Understanding your load capacity needs is the first step in selecting an EOT crane. Determine the maximum weight your operations will handle to ensure the crane can accommodate current and future demands.

Key Considerations:

- Maximum Load Weight : Ensure the crane can handle your heaviest loads.

- Frequency of Lifting : Consider how often the crane will be used daily.

Type of Materials: Different materials may require specific handling features.

2.Determine the Appropriate Span and Lift Height

The span (distance between the crane’s runway rails) and lift height (vertical distance the hook can travel) are crucial for efficient operations.

Key Considerations:

- Workspace Dimensions : Measure the width and height of your facility.

- Obstructions : Account for any obstacles that may affect crane movement.

- Future Expansion : Plan for potential changes in your facility layout.

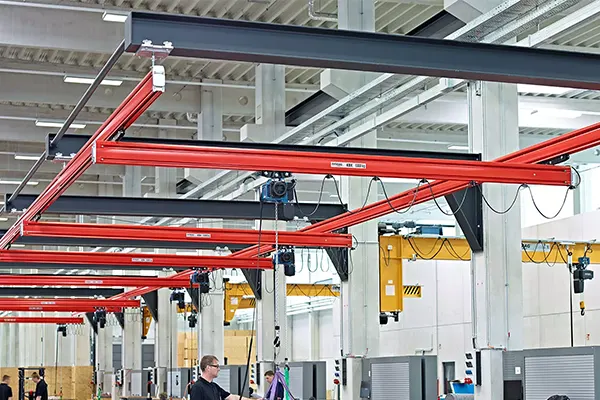

3.Choose Between Single Girder and Double Girder Cranes

The choice between a single girder EOT crane and a double girder EOT crane depends on your load requirements and operational needs.

Single Girder EOT Crane:

- Ideal for light to medium-duty applications.

- Cost-effective and easier to install.

- Suitable for facilities with limited space.

Double Girder EOT Crane:

- Designed for heavy-duty applications.

- Provides higher lifting capacities and greater stability.

Allows for additional features like walkways and maintenance platforms.

4.Evaluate the Duty Cycle

The duty cycle refers to the crane’s operational frequency and duration. Selecting a crane with the appropriate duty classification ensures longevity and performance.

Duty Classifications:

- Class A (Light Duty):Infrequent use with light loads.

- Class B (Moderate Duty):Moderate use with average loads.

- Class C (Heavy Duty):Frequent use with heavy loads.

- Class D (Severe Duty):Continuous use with very heavy loads.

5.Consider Environmental Factors

Your facility’s environment can impact the crane’s performance and longevity.

Key Considerations:

- Temperature Extremes:High or low temperatures may require special components.

- Corrosive Environments:Facilities with chemicals or moisture need corrosion-resistant materials.

Dust and Debris: Dusty environments may necessitate sealed components.

6.Prioritize Safety Features

Ensuring the safety of your operations is paramount. Modern EOT cranes come equipped with various safety features to protect both personnel and equipment.

Essential Safety Features:

- Overload Protection:Prevents lifting beyond the crane’s capacity.

- Emergency Stop Buttons:Allows immediate halting of operations.

- Limit Switches:Controls the crane’s movement range to prevent accidents.

Anti-Collision Systems: Prevents collisions with other equipment or structures.

7.Evaluate Maintenance and Support Services

Regular maintenance ensures the crane’s longevity and optimal performance. Choose a manufacturer that offers comprehensive support services.

Key Considerations:

- Availability of Spare Parts:Ensure easy access to replacement parts.

- Technical Support:Access to expert assistance when needed.

- Training Programs:Operator training for safe and efficient crane use.

8.Analyze Total Cost of Ownership

Beyond the initial purchase price, consider the total cost of ownership, including installation, maintenance, energy consumption, and potential downtime.

Key Considerations:

- Energy Efficiency:Opt for cranes with energy-saving features.

- Durability:Invest in high-quality equipment to reduce long-term costs.

- Warranty and Service Agreements:Understand the terms and coverage provided.

Conclusion

Selecting the right EOT crane involves careful consideration of various factors, including load requirements, crane type, environmental conditions, safety features, and total cost of ownership. By thoroughly evaluating these aspects, you can ensure efficient, safe, and cost-effective operations in your industrial facility.