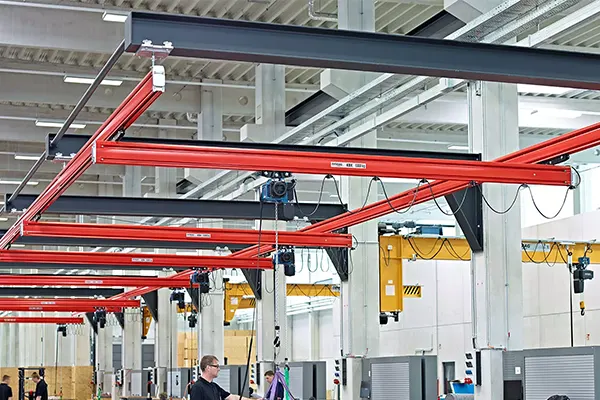

- XY-Zero is an optional software package fitted to the crane, which is designed to totally eradicate load swing caused by travelling movements of the crane.

- The software can be fitted to new or existing pendant, radio or cab controlled cranes.

- Standard software is suitable for heights of lift up to 30 metres.

The XY-Zero software is installed on a frequency inverter or PLC controlled drives and can be used in conjunction with one or both of the crane axis (travel or traverse).

Proximity switches are mounted onto the hoist unit, which provide a constant feedback signal to indicate the hook height at any given point. As the crane motions are operated, the XY-Zero software calculates the predicted swing movement on the load. The crane’s travel and traverse movements are then automatically modified to eliminate any load swing. This provides the operator with greater control over the crane, allowing faster crane cycle times, increasing efficiency.

When lifting using different slings, chains or attachments, the operator adjusts the height correction switch on the crane controller to suit the particular attachment. The multi-position rotary switch uses the input figure for the length of the attachment to fine -tune the pendulum length. This keeps the load steady, eliminating any double pendulum effect that may normally occur.

XY-Zero reduces crane cycle times by a much as 50%

- Safely allows much faster speeds

- Increases operator efficiency

- Soon pays for itself

XY-Zero extends crane life

- Eliminates the need for “jogging”

- Less stress on the crane structure

- Electronic braking saves brake wear

XY-Zero enables affordable automation

- Pre-programmed routines possible

- Works with process integrated automation

XY-Zero prevents load damage

- Reduces risk of collision

- Enables accurate positioning

XY-Zero vastly improves safety

- Reduces operator fatigue

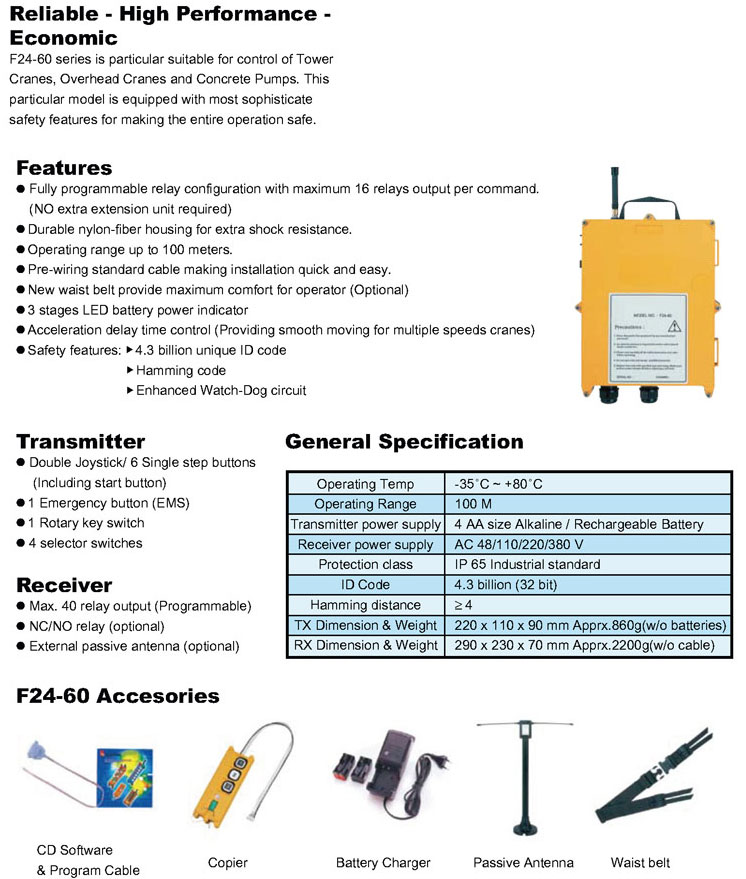

- F24-60 series is particular suitable for control of Tower Cranes, Overhead Cranes and Concrete pumps. This particular model is equipped with most sophisticate safety features for making the entire operation safe.

- Fully programmable relay configuration with maximum 16 relays output per command.(No extra extension unit required).

- Durable nylon-fiber housing for extra shock resistance.

- Operating range up to 100 meters.

- Pre-wiring standard cable making wiring procedures easier.

- New waist belt provide maximum comfort for operator(Optional)

- 3 stages LED battery power indicator.

- Acceleration delay time control(Providing smooth moving for multiple speeds cranes)

- Safety features:4.3 billion unique ID code/Hamming code/Enhanced watch-dog circuit.

F24-60 Transmitter

- Double Joystick

- 6 Single Step Buttons(Including start button)

- 1 Emergency button(EMS),

- 1 Rotary Key Switch.

- 4 Selector Switches

F24-60 Receiver

- Max. 40 relay output (Programmable)

- NC/NO relay (Optional)

- External passive antenna (Optional)

- Operating Temp:-35?C ~ +80?C

- Operating Range:100M

- Transmitter power supply: 4 AA size Alkaline / Rechargeable Battery

- Receiver power supply: AC 48/110/220/380V

- Protection class: IP 65 Industrial standard

- ID Code: 4.3 billion(32 bit)

- Hamming distance: = 4

- Transmitter Dimension & Weight: 220 x 110 x 90 mm Apprx.860g (w/o batteries)

- Receiver Dimension & Weight: 290 x 230 x 70 mm Apprx.2200g (w/o cable)